Views: 0 views

When people want to buy a screen, they often search using keywords like “LCD display” or “LCD screen.” But after contacting a few sellers, they’ll often notice a specific term: LCD module, which professionals usually abbreviate as LCM.

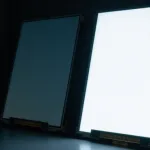

To the buyer, an LCD is a screen. But for manufacturers, a “screen” is actually composed of several parts, an LCD cell, backlight, and optionally a touch panel, assembled into one module. This module includes drive circuits and control circuits and can be directly connected to a buyer’s device. That’s why sellers use the precise term LCD Module.

What Is an LCD Module?

An LCD module is an integrated unit that includes the LCD panel responsible for image display, along with the other essential components that enable it to function properly. Unlike a bare cell, an LCD module can be easily embedded into industrial equipment, handheld devices, vehicle displays, or consumer electronics.

A typical LCD module includes:

- TFT LCD Panel (core display layer)

- Backlight Unit (provides illumination)

- Driver IC (controls image rendering)

- FPC or PCB (for signal and power connection)

- Interfaces (e.g., SPI, RGB, MIPI, LVDS)

- Optional Components: Capacitive Touch Panel (CTP), metal frame, cover glass

At CDTech, we specialize in LCD module manufacturing based on TFT-LCD technology. We provide both standard modules and fully customized solutions tailored to your specific needs.

Differences Among LCD (Cell), LCD Module, and Finished Product

| Feature | LCD (Cell) | LCD Module | Finished Product |

|---|---|---|---|

| Composition | TFT glass layer only | Complete display unit with backlight and circuitry | LCD module plus enclosure, power supply, interface electronics, and other peripherals |

| Ready to display? | No | Yes | Yes |

| Intended use | For module assembly | Direct integration into end products | End-user ready product, complete device |

| Development complexity | Requires driver and backlight design | Plug-and-play, faster development | Minimal, mostly system integration and application software |

In short, the cell is a raw material, the module is a display-ready component, and the finished product is a complete device ready for end use.

The LCD Module Supply Chain

Manufacturing an LCD module is not a matter of simple assembly. Every module requires coordination among multiple specialized upstream suppliers. I previously shared an article explaining the advantages of our Shenzhen-based supply chain, where many of our partners are concentrated. If you have time, I recommend reading it.

As a module manufacturer, CDTech procures and integrates key components from various suppliers:

| Component | Description | Typical Suppliers |

|---|---|---|

| TFT LCD Panel | Core display component with liquid crystal between two glass layers | BOE, HannStar, Innolux, AUO, HKC, etc. |

| Backlight Unit | Provides the necessary light source for the panel | LED backlight module vendors |

| Driver IC | Controls pixels and signal processing | Fitipower, Sitronix, TIANYU, etc. |

| FPC/PCB | Flexible or rigid printed circuit boards | FPC suppliers |

| Touch Screen (optional) | Capacitive touch panel with controller | In-house at CDTech |

| Cover Glass | Protective and aesthetic glass | AGC and others |

We perform full in-house assembly: from cell cutting, polarizer lamination, COG, FOG, backlight integration, touch bonding, to optical/electrical testing and quality assurance.

How Did You Find This Page?

Depending on your industry, we offer different procurement advice.

We’ve received many inquiries from different industries. While most are looking to buy LCD modules, some are seeking finished devices. Below is a categorized list of customer types with corresponding recommendations:

| Customer Type | Typical Use Case | Suitable for Module Purchase? | Notes & Suggestions |

|---|---|---|---|

| End Product Manufacturers (Device OEMs) | Industrial, medical, automotive equipment | Yes | Focus on specs, interface, and customization for easy integration |

| Solution Developers (ODM / IDH) | Design full product solutions for brands | Yes | Choose module makers with strong tech support and documentation |

| Distributors / Channel Agents | Bulk purchasing, inventory for resale | Yes | Prioritize long lifecycle, standard interface modules |

| System Integrators | Embedding modules into automation, kiosks, etc. | Yes | Need industrial-grade performance and interface compatibility |

| End Users (B2B buyers) | Replace or maintain displays in equipment | Maybe | Depends on your tech ability, can buy module or full device |

| Small OEMs / Prototype Developers | Sample development, low-volume runs | Suitable | Work with suppliers offering samples and support |

| Repair Shops / Refurbishers | Replace screens in phones, laptops | No | CDTech does not supply these screens, find a specialized supplier |

| DIYers / Education / Individual Retail | Small-volume, experiments, projects | No | Buy via e-commerce or agents; consider ready-to-use kits |

| Installation Contractors | Focus on equipment installation | No | Coordinate with end-device makers or integrators |

| Cross-industry Buyers (Furniture, Culture Projects, etc.) | Government bidding, public installation | No | Usually require full finished products, work with solution providers |

Final Thoughts

This article explains the production flow from LCD Cell → Module → End Product. If you plan to purchase displays, it’s critical to first determine whether you need a module or a complete device. We often receive inquiries for full devices, but we politely decline, our lines are not set up for casing or finished products, as that’s not our core specialty.

Still, knowing your target purchase helps you find the right supplier faster. In our next article, I’ll explain how to effectively request customization from us. Some requests require coordination with component vendors, some require internal design changes, and some may not be feasible, so I’d rather help you understand what’s truly customizable.

Thank you for reading. If you have needs, feel free to reach out to me or contact CDTECH.

Leave a Reply